Infrastructure

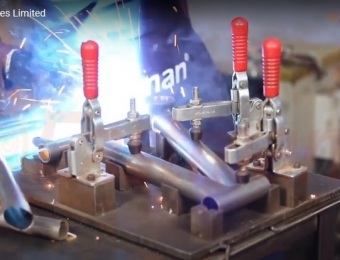

“Eastman Global has a state-of-the-art infrastructure, latest equipment’s and proven techniques to manufacture top-quality products. We procure raw materials to manufacture bicycle parts and accessories from the certified vendors to ensure quality and authenticity. In order to cater to different requirements and achieve 100% customer satisfaction, Â we has established quality check centers in India and China.

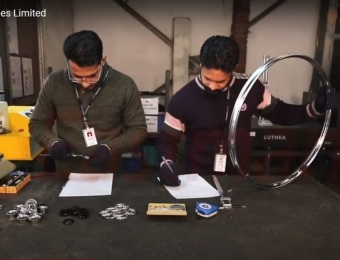

Our manufacturing unit in India and quality check centers in China (Tianjin & Hangzhou) are fully equipped with latest equipment’s, including Universal Testing machine, NSS Testing machines, Rockwell Hardness machine, Chain Wheel load testing machine, Pedal deflection machine, and more. We test all materials through these equipment’s as per the sample plan referred to match international Bicycle Quality standards.

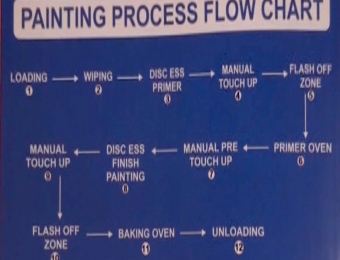

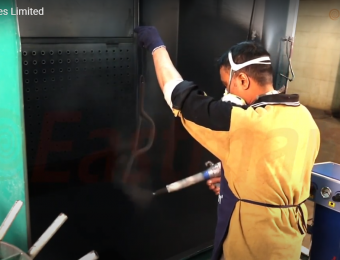

- Fully automatic disc based Painting process, Discs are imported from OTSON, Taiwan both for primer & paint

- Annual Capacity of rolling out 2,70,000 bikes

- 11 tank Phosphating Process to ensure the long life of paint

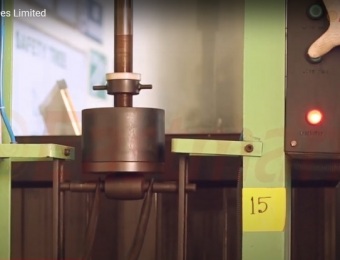

- Semi automatic conveyor based mechanism for error free handling of goods

- Fully equipped laboratory for chemical testing as well as paint quality testing

- Fully equipped laboratory for checking quality parameters of all components sourced from local vendors

- Panel of highly expert engineers for overall product quality

- Accreditated & Certified by BSCI (Business Social Compliance Initiative)

We at Eastman Industries Limited, have streamlined all process and mechanism with advance technology in order to increase production and labor safety.